Overview

While there have been significant strides in prosthetic technology, comparatively little progress has been made to the interface between the user and the device.

Sockets that form the interface between the patient and the device are static, whereas limbs are dynamic.

The limbs themselves experience shape change daily, seasonally, and progressively.

Many users put on and take off layers of socks throughout the day to keep their sockets attached.

A friend and I developed the idea for a new type of prosthetic socket in a medical robotics class which we both took in our senior year at the University of Maryland.

The two of us created a company based on our idea called Adaptive Motion Technologies LLC.

We did extensive research into the market, including meetings with doctors, prosthetists, and amputees.

We developed IP and submitted provisional and full patents based on our idea.

Design Challenge

How can we address the needs of lower limb amputees who often experience discomfort due to poorly fitting prosthetic devices?

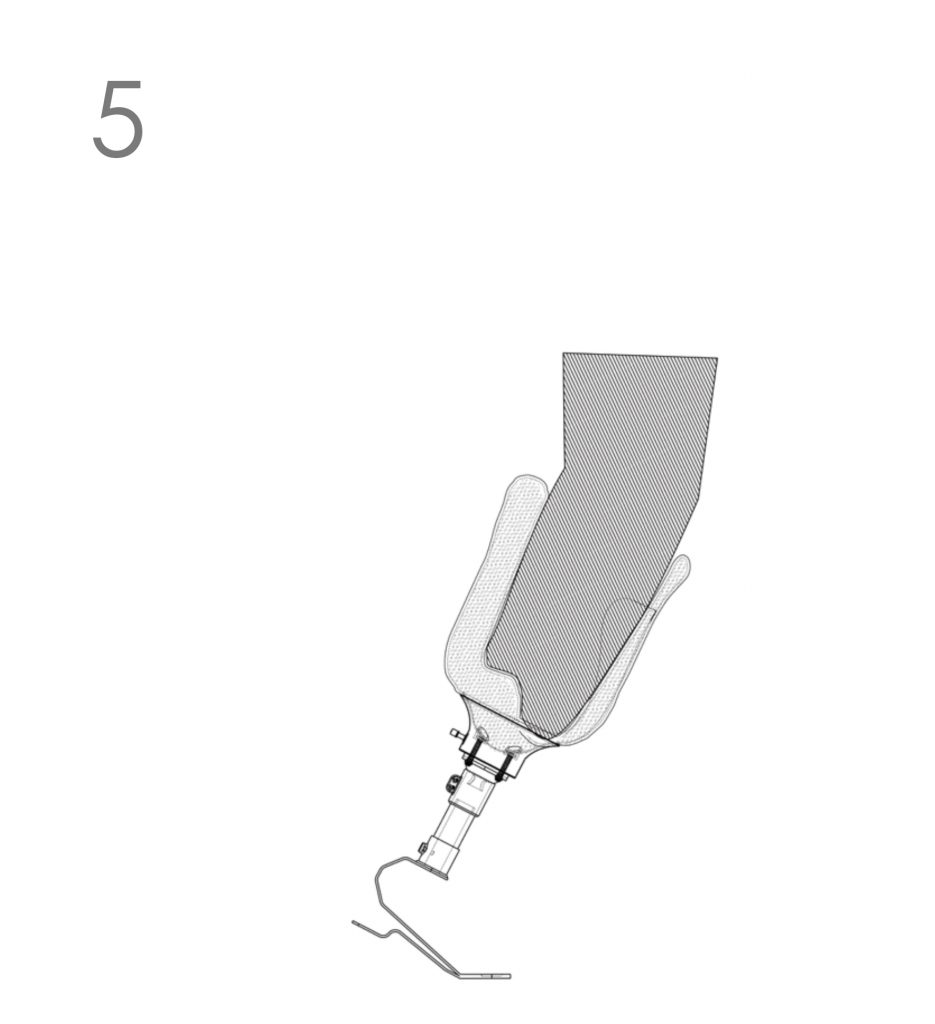

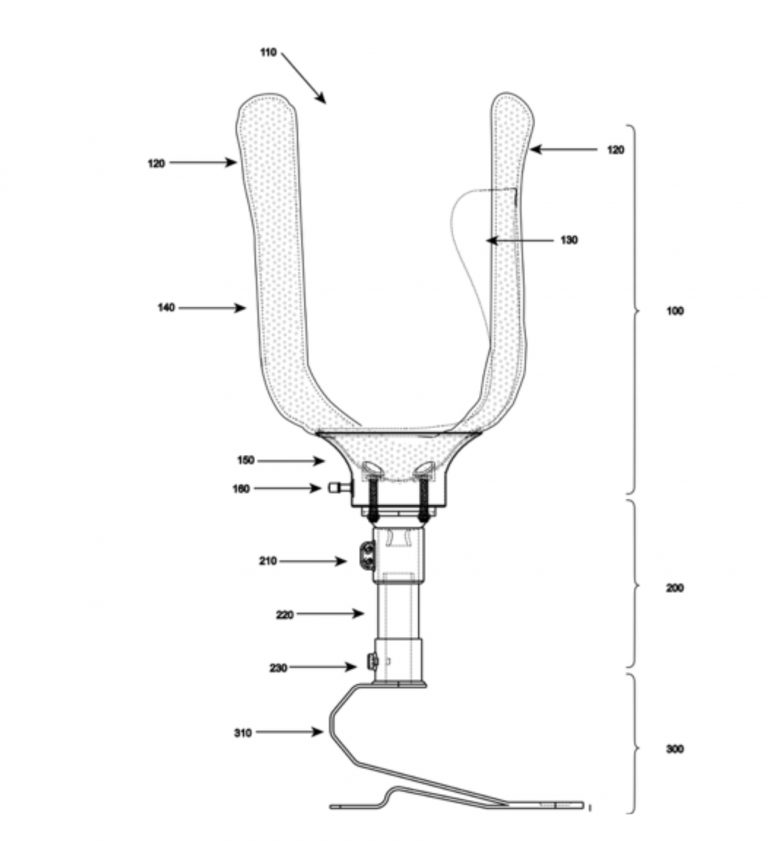

Concept

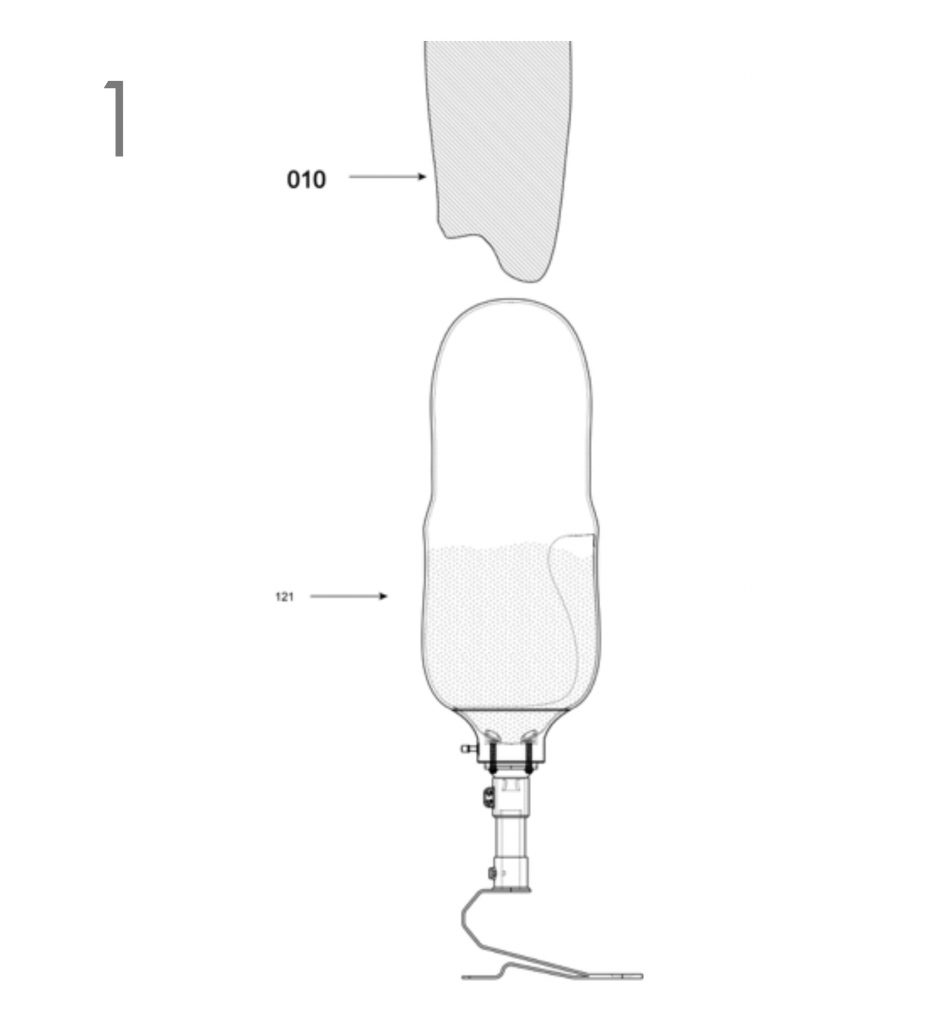

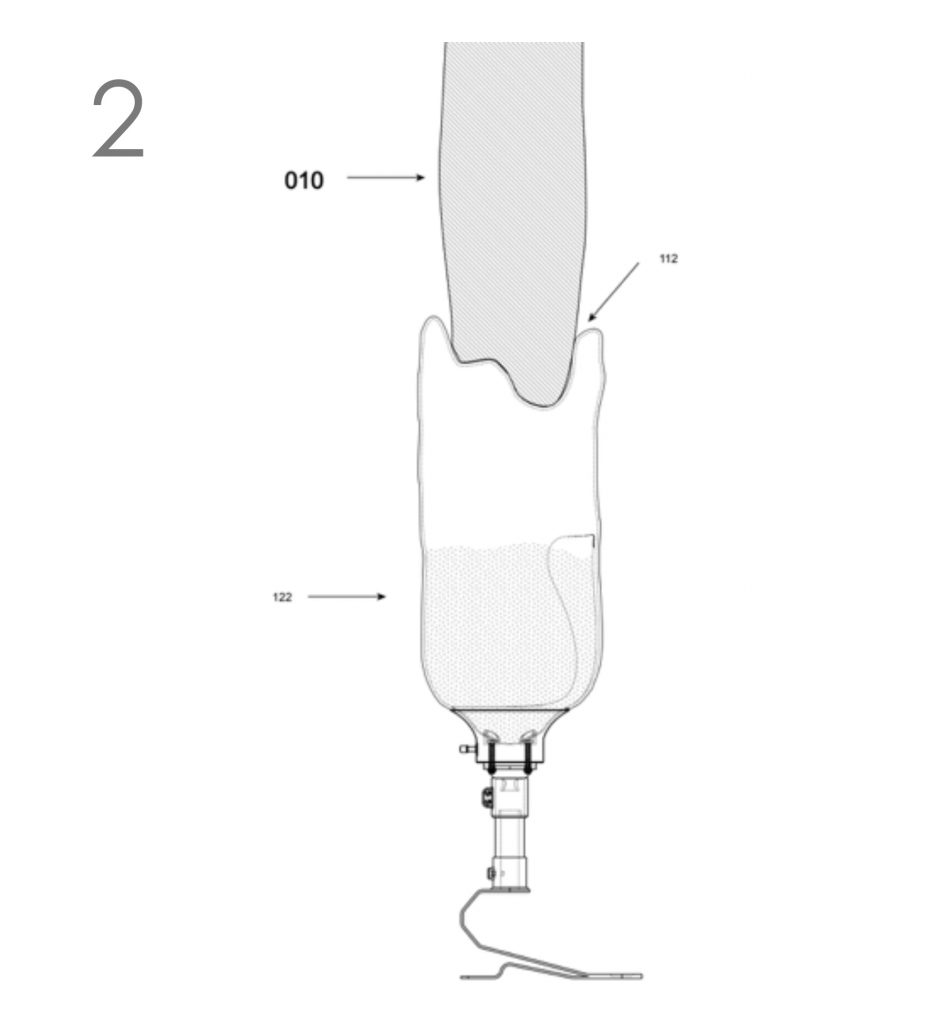

- The socket has a bladder with a granular particulate matter inside; at atmospheric pressure, the granular material simulates a liquid allowing the material to take the shape of the patient’s leg.

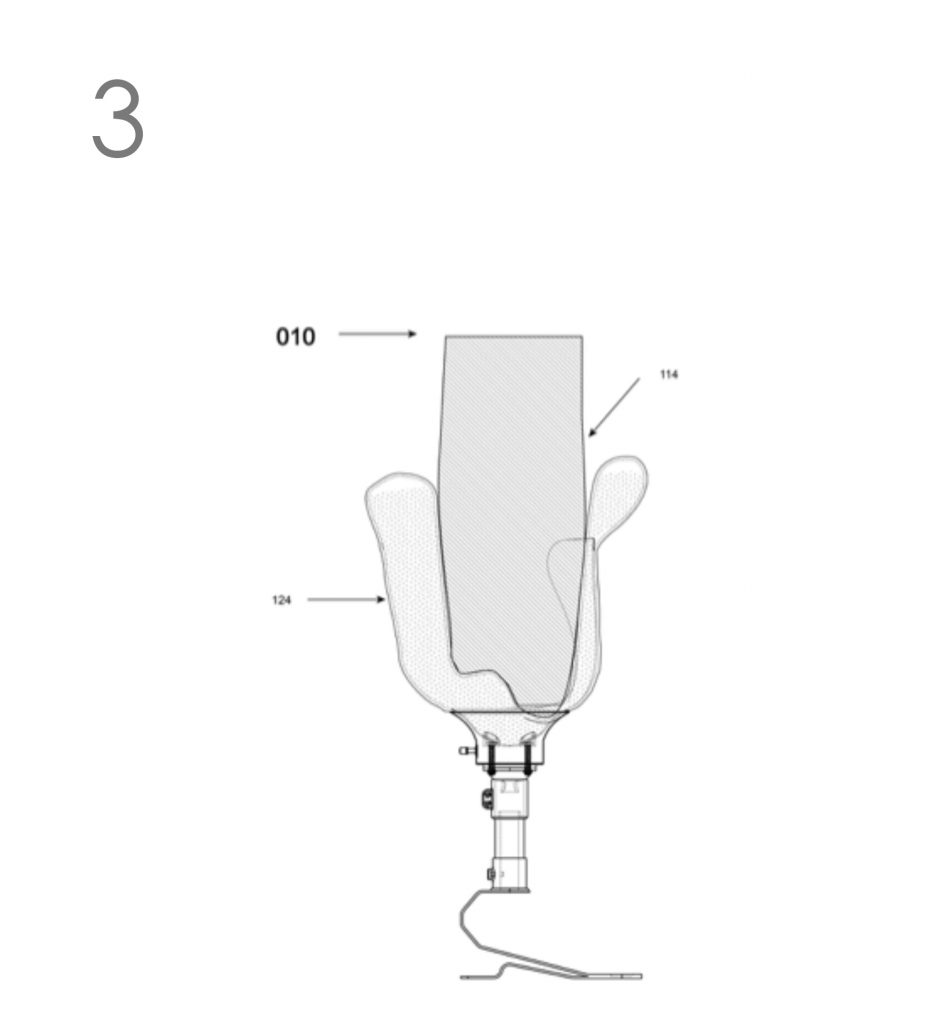

- – 3. The limb can be “rolled” into this bladder displacing the granular material.

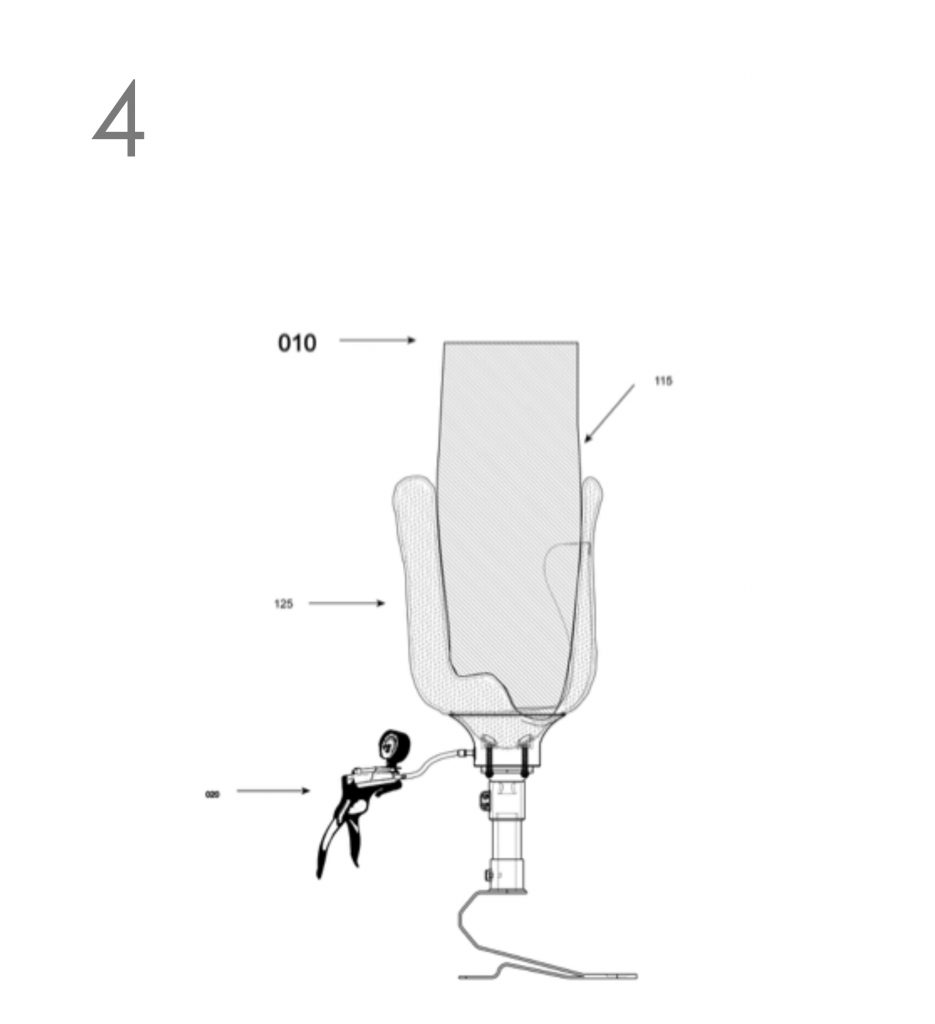

- Once in position, a pump is used to apply a vacuum to the bladder, jamming the particles together, resulting in a rigid solid structure that is now formed correctly to the current conditions of the limb.

- The pump can then be detached.

The mold can reform on the fly with a small portable pump to accommodate the changing conditions of the limb.

Design

Development

After numerous prototypes and significant research, we determined that the costs and barriers of bringing this idea to market were prohibitive, and we retired the company.

In particular, reimbursement policies and the FDA approval process created significant risk for our idea.

If developed further, this idea could be implemented as a postoperative device:

- the shape-changing abilities of the design would benefit the patient when the limb is changing most drastically immediately after limb loss

- this socket would give doctors easy access to the limb to check for proper healing or possible infection

- limited mobility of the patient would allow for a less mechanically rigid socket

Thanks To

My partner in crime and oldest friend, Jonathan Howarth.

William Herlands and Ayelet Lobel, two of the most impressive people to work with that I know.

Terry Elan, who patiently showed me how to make prosthetic sockets, lent me equipment and introduced me to numerous contacts.

Countless doctors and amputees that gave their time, knowledge, and advice.